Difference between revisions of "Jenny corexy voron V1.2 mainpage"

Warriorlious (talk | contribs) |

Warriorlious (talk | contribs) |

||

| Line 32: | Line 32: | ||

====PID==== | ====PID==== | ||

use this command to calibrate hotend pid: | use this command to calibrate hotend pid: | ||

PID_CALIBRATE HEATER=extruder TARGET= | |||

'''PID_CALIBRATE HEATER=extruder TARGET=220''' | |||

And this command to calibrate bed pid: | And this command to calibrate bed pid: | ||

PID_CALIBRATE HEATER=heater_bed TARGET=60 | |||

'''PID_CALIBRATE HEATER=heater_bed TARGET=60''' | |||

when finished will have some information like this: | when finished will have some information like this: | ||

| Line 50: | Line 52: | ||

Prepare for the test by issuing the following G-Code command: | Prepare for the test by issuing the following G-Code command: | ||

SET_VELOCITY_LIMIT SQUARE_CORNER_VELOCITY=1 ACCEL=500 | '''SET_VELOCITY_LIMIT SQUARE_CORNER_VELOCITY=1 ACCEL=500''' | ||

This command makes the nozzle travel slower through corners to emphasize the effects of extruder pressure. Then for printers with a direct drive extruder run the command: | This command makes the nozzle travel slower through corners to emphasize the effects of extruder pressure. Then for printers with a direct drive extruder run the command: | ||

TUNING_TOWER COMMAND=SET_PRESSURE_ADVANCE PARAMETER=ADVANCE START=0 FACTOR=.005 | '''TUNING_TOWER COMMAND=SET_PRESSURE_ADVANCE PARAMETER=ADVANCE START=0 FACTOR=0.005''' | ||

After that,print this gcode: | After that,print this gcode: | ||

The pressure_advance value can then be calculated as pressure_advance = <start> + <measured_height> * <factor>. (For example, 0 + 12.90 * .005 would be 0.0645.) | The pressure_advance value can then be calculated as pressure_advance = <start> + <measured_height> * <factor>. (For example, 0 + 12.90 * .005 would be 0.0645.) | ||

Insert pressure_advance value in printer.cfg. | Insert pressure_advance value in printer.cfg. | ||

JENNY COREXY BGM extuder pressure_advance = 0.046 about. | |||

more info see [https://github.com/KevinOConnor/klipper/blob/afca515e2c2db240b4d354a0ae665479894ef89b/docs/Pressure_Advance.md Klipper pressure] | more info see [https://github.com/KevinOConnor/klipper/blob/afca515e2c2db240b4d354a0ae665479894ef89b/docs/Pressure_Advance.md Klipper pressure] | ||

Revision as of 10:16, 17 August 2021

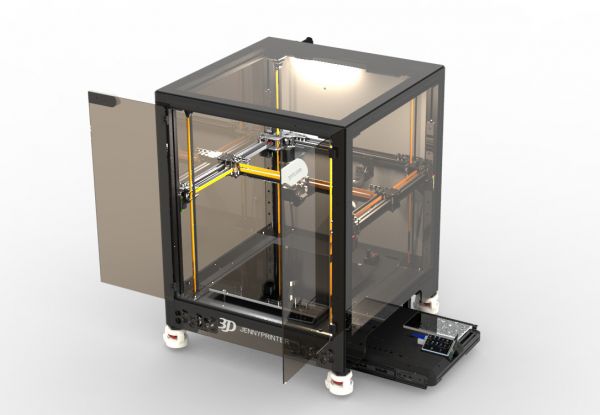

Overview

this is mainpage of jenny corexy 3d printer V1.2

jenny corexy is a metallized structure inspire by vorondesign voron2.4.

we use a more stable 4040 extrusions frame,but keep 2020 extrusions as gantry let it not too heavy. The gantry use a 9mm widened belt,to keep a bigger print size. Also expanded the width of the linear rails.

All structural part use aluminum sheet with stainless steel column let printer can stable in high temperature environment.But some of the beautiful parts that don't matter are whit 3D printed.

I also modified the leveling probe, using a structure I named JennyTouch. It is a contact type photoelectric sensor mechanism,can probe aluminum 、PEI、 glass and any solid platform.

Resources

Communication

- discuss (trouble shooting and feature suggestions)

- facebook (assembly show and printing show)

- youtube (Serial Request and development show)

- discord (timely communication)

Brief assembly instructions

preparatory work

Attention

setup firmware

Debugging

PID

use this command to calibrate hotend pid:

PID_CALIBRATE HEATER=extruder TARGET=220

And this command to calibrate bed pid:

PID_CALIBRATE HEATER=heater_bed TARGET=60

when finished will have some information like this:

PID parameters: pid_Kp=18.731 pid_Ki=0.827 pid_Kd=106.065 The SAVE_CONFIG command will update the printer config file with these parameters and restart the printer.

Use this PID value in printer.cfg

more info see Klipper PID calibrate.

Pressure

Prepare for the test by issuing the following G-Code command:

SET_VELOCITY_LIMIT SQUARE_CORNER_VELOCITY=1 ACCEL=500

This command makes the nozzle travel slower through corners to emphasize the effects of extruder pressure. Then for printers with a direct drive extruder run the command:

TUNING_TOWER COMMAND=SET_PRESSURE_ADVANCE PARAMETER=ADVANCE START=0 FACTOR=0.005

After that,print this gcode:

The pressure_advance value can then be calculated as pressure_advance = <start> + <measured_height> * <factor>. (For example, 0 + 12.90 * .005 would be 0.0645.)

Insert pressure_advance value in printer.cfg.

JENNY COREXY BGM extuder pressure_advance = 0.046 about.

more info see Klipper pressure